Building Long-Term Partnerships with Haining Chuangxing Warp Knitting Fabrics

Success in the international textile market increasingly depends on the ability to create and nurture lasting business relationships that drive steady growth and market leadership. Haining Chuangxing Warp Knitting Co. Ltd., a prominent player in the warp knitting fabric industry, exemplifies how commitment to quality, innovation, and customer service can foster enduring business relationships around the world.

Founded in the early 2000s, Haining Chuangxing has steadily evolved from a regional fabric manufacturer into a high-tech enterprise recognized nationally for its warp knitting fabric production. Located in the scenic city of Haining within Zhejiang province, the company benefits from an industrial environment rich in textile expertise and technological advancement. Over the years, it has developed a strong foundation built on modern manufacturing infrastructure, skilled personnel, and an unwavering focus on research and development.

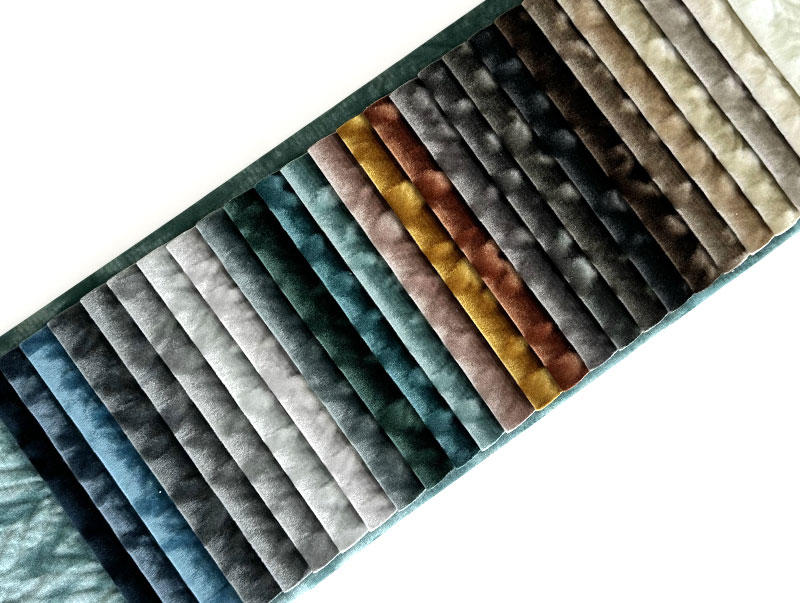

The company’s production base spans an impressive area, equipped with state-of-the-art machinery that supports efficient and precise manufacturing processes. This capacity enables Haining Chuangxing to deliver a wide range of warp knitting fabrics tailored to the specifications and demands of various industries, including apparel, automotive, medical textiles, and home furnishings. The versatility of warp knitting fabrics produced here has contributed significantly to the company’s reputation for reliability and product excellence.

One of the core strengths of Haining Chuangxing lies in its comprehensive business model that integrates the entire product lifecycle—from initial design and development to manufacturing and global sales. This end-to-end approach allows for streamlined coordination, quality control, and innovation at every stage, ensuring customers receive fabrics that meet both aesthetic and functional requirements. By investing continuously in technology and innovation, the company stays ahead of market trends, introducing new fabric textures, performance characteristics, and sustainable materials that appeal to environmentally conscious buyers.

Haining Chuangxing’s impact extends far beyond domestic borders. Its warp knitting fabrics are distributed to over 100 countries and regions worldwide, demonstrating a truly global footprint. The company holds substantial market shares in regions such as North America, Turkey, South Korea, South Africa, and Southeast Asia. These international markets demand high standards in fabric quality and supply chain reliability—requirements that Haining Chuangxing consistently fulfills through rigorous quality management and proactive client engagement.

Moreover, the company’s commitment to building long-term partnerships is evident in its customer-centric philosophy. Understanding that successful business collaborations rely on trust, transparency, and responsiveness, Haining Chuangxing prioritizes clear communication and flexible service solutions. Whether addressing custom fabric orders, meeting urgent delivery schedules, or providing technical support, the company aims to exceed customer expectations at every interaction. This approach has earned Haining Chuangxing a solid reputation among its global clientele, many of whom have established repeat business and joint development projects with the company.

Sustainability is increasingly becoming a focus area for fabric manufacturers worldwide. While maintaining high performance and quality standards, Haining Chuangxing also explores environmentally responsible production methods. This aligns with global trends and customer preferences, further enhancing its appeal as a trustworthy and forward-thinking partner in the warp knitting fabric industry.

Haining Chuangxing Warp Knitting Co. Ltd. stands out as a model enterprise that balances technological innovation, broad market reach, and customer partnership. Its ability to provide high-quality warp knitting fabrics coupled with excellent service and international distribution makes it a preferred choice for businesses seeking reliable fabric suppliers. By nurturing long-term relationships founded on shared goals and mutual growth, Haining Chuangxing continues to strengthen its position as a leader in the global textile industry.