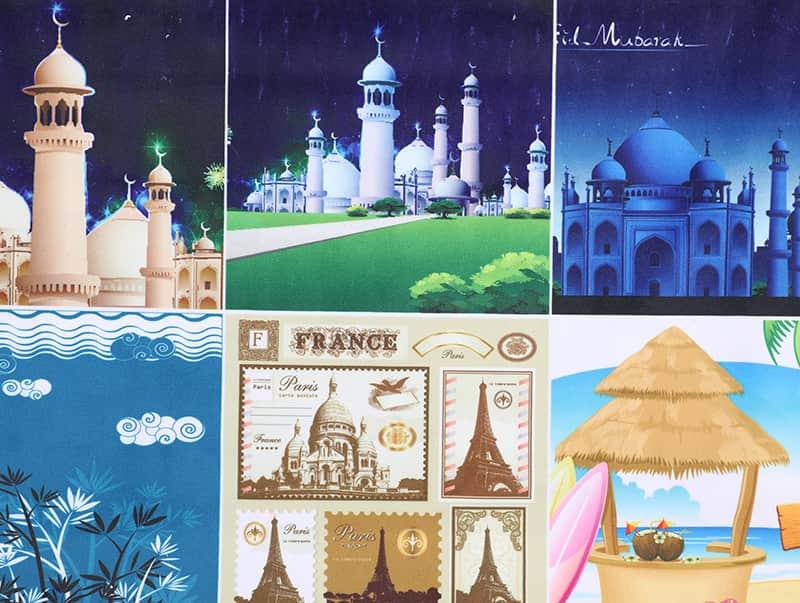

What is the effect of PFP-treated fabrics on printing?Fabrics treated with PFP (Prepared For Printing) can usually provide good printing effects. PFP treatment is mainly to improve the ink absorbency and printing effect of the fabric surface, so that the printed pattern can be clearly and vividly transmitted to the fabric. The following are the effects of PFP-treated fabrics on several aspects of printing effects:

Pattern clarity: The surface of the PFP-treated fabric is smoother, and impurities and hairiness are removed, which helps ensure the clarity and detail of the printed pattern.

Color vividness: PFP treatment can enhance the fabric's absorption of pigments, making it easier for colors to be transferred to the fabric and making the colors more vivid and bright.

Printing accuracy: Since PFP treatment improves the ink absorbency of the fabric surface, the printing pattern can be more accurately transmitted to the fabric, reducing printing errors and blurriness.

Dye permeability: PFP treatment usually improves the fiber structure of the fabric and increases its dye permeability, making it easier for the dye to penetrate into the fiber and improving the uniformity and stability of dyeing.

Printing adhesion: PFP treatment can improve the adhesion of the fabric surface, making the printed pattern adhere more firmly to the fabric, reducing the risk of falling off after printing.

Fabrics treated with PFP can usually provide the good performance required for printing, including clarity, color vibrancy, accuracy and adhesion. This makes PFP-treated fabrics a commonly used choice in the textile printing industry, which can meet the needs of the printing process and achieve high-quality printing effects.

How to increase the dye permeability of PFP/PFD fabrics (for printing/dying)?PFP (Prepared For Printing, for printing) and PFD (Prepared For Dyeing, for dyeing) fabrics have taken some treatment measures to increase the dye permeability, making it easier for the dye to penetrate into the fiber, thereby achieving uniformity and stability of dyeing. . Here are some common methods:

Surface treatment: PFP and PFD treatment usually include treatment of the surface of the fabric to improve its fiber structure and surface morphology. Through surface treatment, the fiber surface can be made smoother and more uniform, hairiness and roughness can be reduced, and dye permeability can be improved.

Bleaching: In PFD treatment, the fabric is often bleached to remove residual pigments, impurities, grease and other substances, making the fiber more pure and transparent, thus improving the permeability of the dye.

Pre-shrinking treatment: Before dyeing, PFD fabrics are usually pre-shrunk to reduce the porosity and gaps of the fibers, thereby reducing the loss of dye during the dyeing process and improving the permeability and fixation of the dye.

Chemical treatment: The fabric undergoes some special chemical treatment, such as alkaline or acid treatment, which can change the surface properties of the fiber, increase its affinity for dyes, and promote the penetration and fixation of dyes.

Softener treatment: In some dyeing or printing processes, softeners and other treatment agents can be added to make the fiber softer and easier to penetrate, thereby improving the dye's permeability.

PFP and PFD fabrics can effectively increase the permeability of dyes, making the dyeing or printing process smoother and more uniform, and the final dyeing effect more stable and lasting.