Correct seam construction and sealing techniques play a crucial role in maintaining the waterproof and moisture-resistant properties of artificial leather base fabric. Here's how:

Preventing Water Ingress: Proper seam construction ensures that seams are securely bonded or stitched together, minimizing the risk of water seepage through stitch holes or gaps in the seam. Water can penetrate through poorly constructed seams, compromising the fabric's waterproofing and allowing moisture to reach the underlying layers.

Maintaining Fabric Integrity: Seam construction techniques that distribute stress evenly along seam lines help maintain the integrity of artificial leather base fabric, especially in areas subjected to tension or mechanical stress. Strong and durable seams prevent fabric distortion, tearing, or separation, ensuring long-lasting performance and durability.

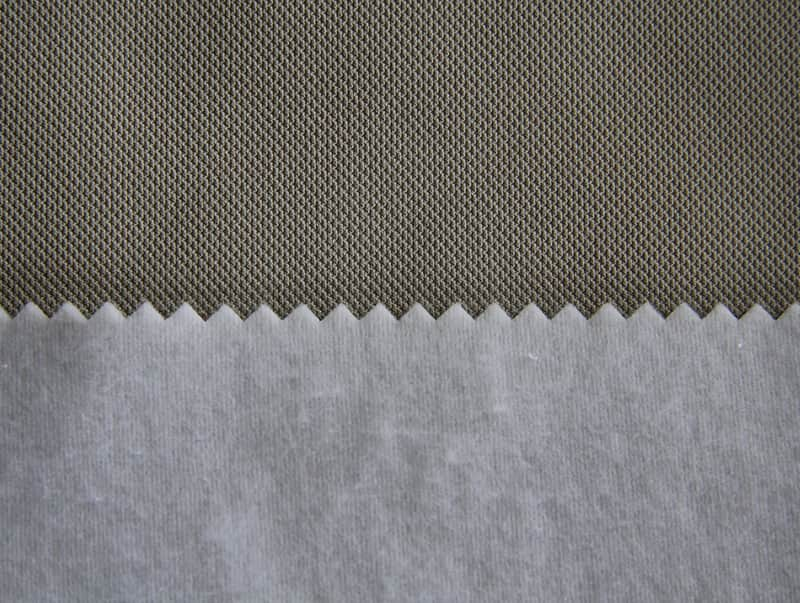

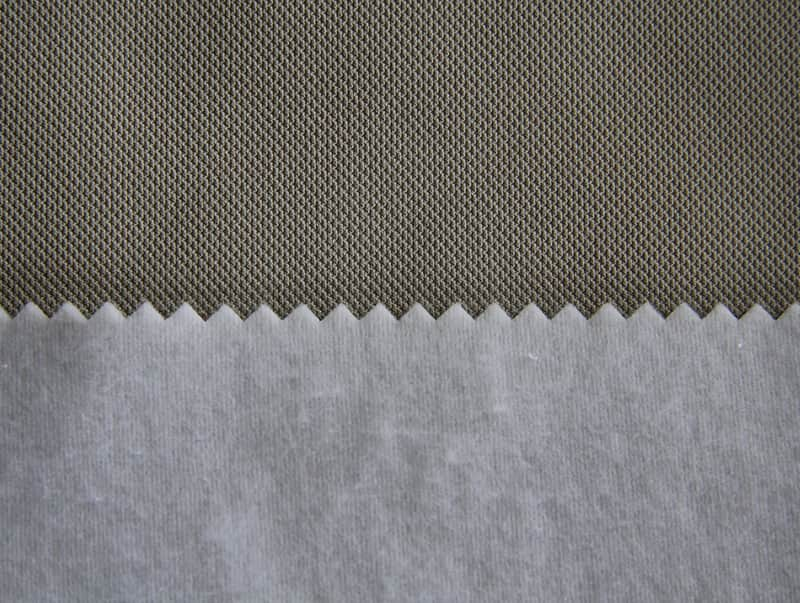

Enhancing Waterproofing: Seam sealing techniques, such as heat sealing, adhesive bonding, or waterproof tape application, create a watertight barrier along seam lines, preventing water from entering the fabric through seams. Seam sealing complements the waterproof coatings or treatments applied to the fabric surface, providing additional protection against water ingress and moisture penetration.

Preventing Leaks and Staining: Properly sealed seams prevent leaks and seepage of water or liquids through the fabric, reducing the risk of interior damage or staining in applications such as upholstery, automotive interiors, or outdoor gear. Waterproof seam sealing ensures that artificial leather base fabric maintains its appearance and performance even when exposed to wet or humid conditions.

Enhancing Aesthetic Appeal: Neat and well-executed seam construction contributes to the overall appearance and aesthetic appeal of artificial leather base fabric products. Seam lines that are smooth, flat, and free of puckering or irregularities enhance the fabric's visual appeal and perceived quality, making it more desirable for various applications.

Ensuring Long-Term Performance: Correct seam construction and sealing techniques contribute to the fabric's long-term performance and reliability, particularly in outdoor or high-moisture environments where exposure to water, humidity, and temperature fluctuations can accelerate deterioration. Properly sealed seams maintain the fabric's waterproofing properties and structural integrity over time, extending its service life and reducing the need for repairs or replacements.

Correct seam construction and sealing techniques are essential for maximizing the waterproof and moisture-resistant properties of artificial leather base fabric, ensuring that it remains durable, functional, and aesthetically pleasing in diverse applications.