There can be variations in material blends and treatments for automobile headliner fabrics, and these variations often depend on the specific requirements and applications within the automotive industry. Here are some common considerations regarding material blends and treatments for different applications:

Material Blends:

Manufacturers may use different material blends for headliner fabrics to achieve specific performance characteristics. Common materials include polyester, nylon, olefin, and blends of these fibers.

Blends are often chosen based on factors such as durability, flexibility, cost, and aesthetic appeal.

Foam Backing:

Some headliner fabrics may have foam backing applied during the manufacturing process. The foam backing can enhance the fabric's ability to conform to the contours of the vehicle interior, provide additional cushioning, and contribute to sound insulation.

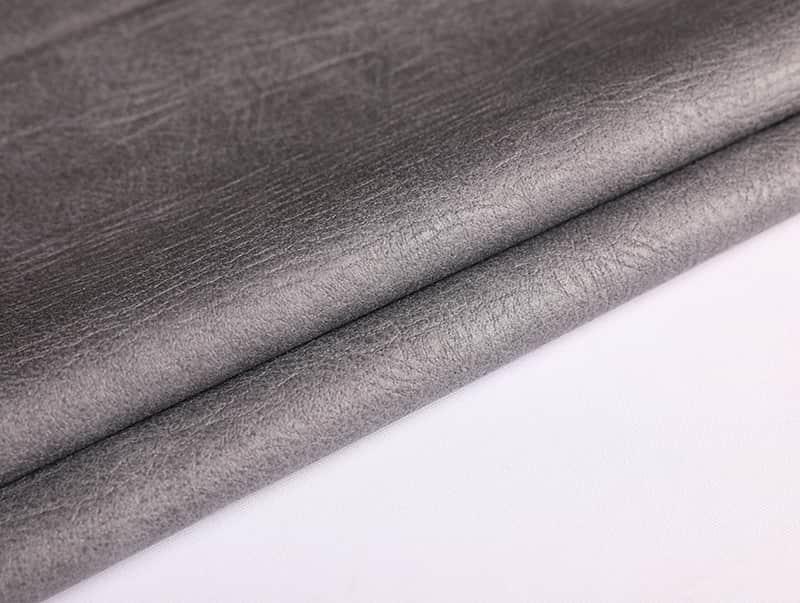

Laminations and Coatings:

Headliner fabrics may undergo lamination or coating processes to impart additional properties. For example, laminations can enhance strength and durability, while coatings may improve resistance to stains, water, or UV radiation.

Fire Retardant Treatments:

Due to safety considerations, certain headliner fabrics may undergo treatments to make them fire retardant. This is especially important to meet safety standards for automotive interiors.

Anti-Microbial Treatments:

In some applications, especially those where cleanliness is a priority, headliner fabrics may be treated with anti-microbial agents to inhibit the growth of bacteria or fungi. This can be relevant for public transportation or shared vehicle applications.

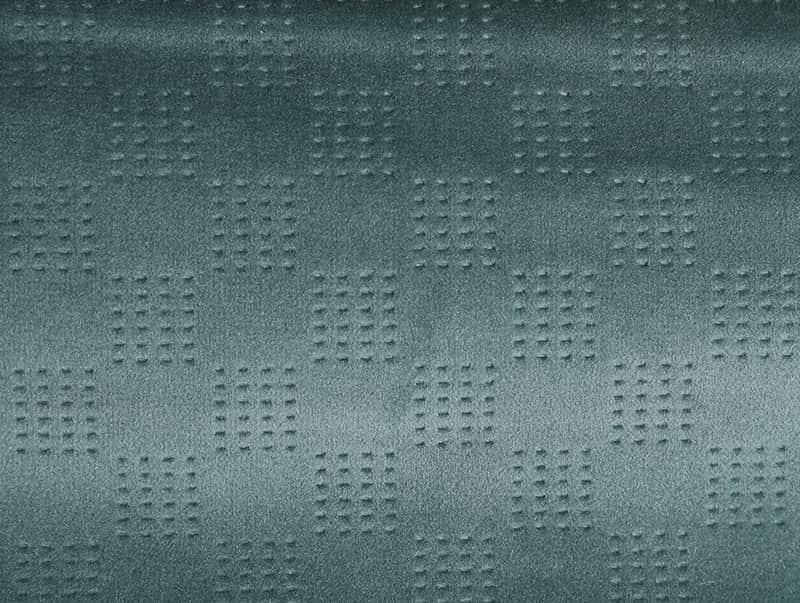

Color Treatments:

Manufacturers offer a variety of color treatments and dyeing processes to achieve a wide range of colors and patterns for headliner fabrics. Color treatments may also include UV-resistant pigments to prevent fading.

Environmentally Friendly Options:

With an increased focus on sustainability, some headliner fabrics may be developed using environmentally friendly materials or processes. This can include recycled fibers or production methods that minimize environmental impact.

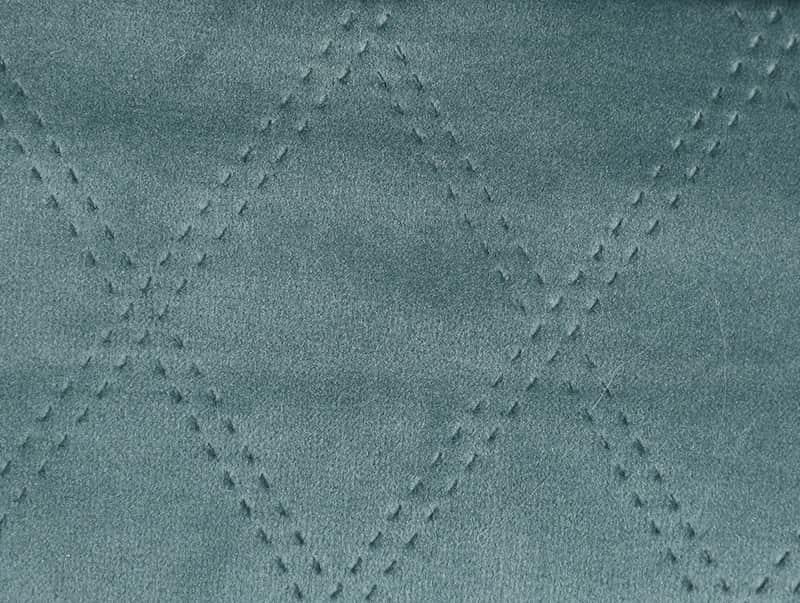

High-Performance Fabrics:

For luxury or high-performance vehicles, headliner fabrics may be engineered with advanced materials to provide comfort, acoustic performance, and aesthetic appeal. These fabrics may have special coatings or treatments to meet the specific demands of premium vehicles.

Acoustic Treatments:

Headliner fabrics in vehicles may undergo treatments to enhance acoustic performance. This can include the incorporation of acoustic materials or special weaves that contribute to sound absorption and insulation within the vehicle cabin.

Customization for OEMs:

Original equipment manufacturers (OEMs) often collaborate with fabric suppliers to develop custom solutions for their vehicles. This may involve tailored material blends and treatments to align with the design and performance specifications of a particular automobile model.

Durability and Abrasion Resistance:

Depending on the application, headliner fabrics may receive treatments to enhance durability and resistance to abrasion. This is particularly important for areas prone to wear and tear, such as the headliner near entry points.